10 Costly Mistakes to Avoid When Ordering Custom Parts from China (2025 Guide)

Ordering custom parts from China offers businesses worldwide access to cost-effective manufacturing, specialized production capabilities, and flexible customization—when done right. However, 7 out of 10 buyers report facing delays, quality discrepancies, or budget overruns due to preventable errors. Whether you’re sourcing USA custom hardware parts, automotive components customization, or precision machining for medical equipment parts, avoiding these critical mistakes will save you time, money, and frustration.

As a leading integrated manufacturing and trading company based in Shenzhen, Shenzhen Sunmy Hardware Co., Ltd. has helped global clients navigate custom parts sourcing since 2016. With our robust production systems (Casting/Lathe/Machining/Stamping/Injection Molding) and expert team skilled in turning drawings/samples into high-quality custom parts, we’ve identified the most common pitfalls—and how to steer clear of them.

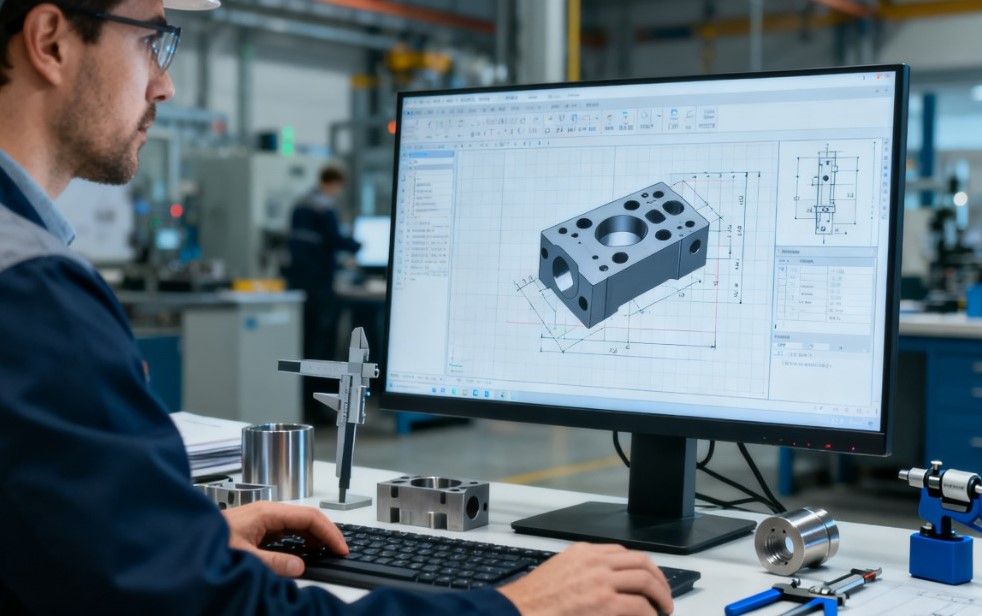

1. Vague Technical Specifications (No Detailed Drawings or Samples)

One of the biggest mistakes buyers make is providing vague descriptions like “a small aluminum bracket” instead of precise 2D/3D drawings (e.g., CAD files) or physical samples. Without clear dimensions, tolerances, material grades, or surface finish requirements, manufacturers can’t accurately quote or produce parts that match your needs. This leads to rework, delays, and wasted resources.

Solution: Invest time in refining your technical specs. Provide detailed drawings with annotations, material codes (e.g., 6061 aluminum for electronic components), and tolerance limits. If you have a sample, share it with your supplier for reference. At Sunmy Hardware, we specialize in custom lathe parts according to drawing and custom electronic components manufacturing—our engineering team works closely with clients to clarify ambiguities and ensure every detail is translated into production.

2. Ignoring Manufacturer’s Production Capability Verification

Not all Chinese manufacturers have the equipment or expertise to handle your custom project. Choosing a supplier without verifying their production capabilities (e.g., CNC machining, die casting, injection molding) often results in subpar parts or missed deadlines. For example, a supplier specializing in plastic injection molding may struggle with aluminum die casting parts, leading to quality issues.

Solution: Vet suppliers thoroughly by reviewing their production facilities, certifications, and case studies. Ask for details on their machinery, quality control processes, and experience with your specific part type. At Sunmy Hardware, our Production Capability page outlines our comprehensive manufacturing solutions—from stamping service for stainless steel brackets to injection molding solutions for plastic parts—so you can confirm we’re equipped to deliver your project.

3. Skipping the Prototype Confirmation Step

Many buyers rush to mass production to save time, skipping the prototype phase. This is risky: even with detailed specs, prototypes reveal design flaws, fit issues, or material inconsistencies that aren’t visible on paper. For example, a custom metal part may look correct in a drawing but fail to assemble with your other components.

Solution: Always request a prototype before full production. Test the prototype for fit, function, and durability, and provide feedback for adjustments. Sunmy Hardware offers rapid prototyping services for OEM machining parts and custom spare parts, allowing you to validate your design without committing to large orders. Our team uses the same production processes for prototypes as mass production, ensuring consistency.

4. Overlooking Material Quality Requirements

Material quality directly impacts part performance—yet many buyers fail to specify or verify material standards. For instance, using low-grade aluminum instead of aerospace-grade aluminum for custom aluminum machining parts for electronics can lead to premature failure. Similarly, substandard plastics may not withstand industrial environments for precision plastic components.

Solution: Clearly state material requirements (e.g., ASTM, ISO, or SAE standards) in your contract. Ask for material certificates (e.g., Mill Test Reports) to confirm compliance. As an experienced die casting manufacturer and industrial parts supplier, Sunmy Hardware sources materials from trusted vendors and provides full transparency on material specifications—no cutting corners.

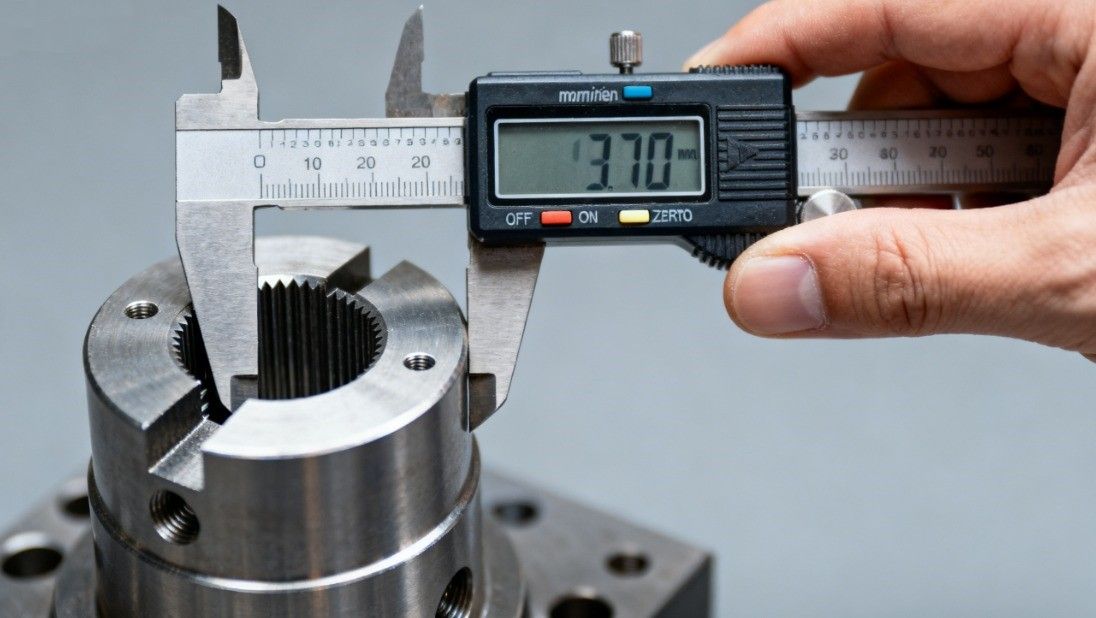

5. Neglecting Quality Control (QC) Protocols

Without robust QC processes, you risk receiving batches of defective parts. Common QC oversights include not defining inspection criteria, skipping in-process checks, or failing to conduct final inspections before shipment. This is especially critical for high-precision parts like precision machining for medical equipment parts.

Solution: Work with your supplier to establish QC protocols:

- In-process inspections (e.g., checking dimensions during machining)

- Final inspections (e.g., visual checks, dimensional testing, functional testing)

- Acceptance criteria (e.g., AQL standards for defect rates)

Sunmy Hardware integrates QC at every stage of production. Our team uses advanced measuring tools to ensure parts meet your specifications, and we provide inspection reports upon request—giving you peace of mind.

6. Unclear Lead Time and Shipping Terms

Miscommunication about lead times and shipping can derail your project timeline. For example, a supplier may quote a 30-day lead time for custom parts manufacturer in China, but fail to mention production delays due to material shortages. Similarly, unclear shipping terms (e.g., EXW vs. DDP) can lead to unexpected costs.

Solution: Get written confirmation of lead times (including production, testing, and shipping) and clarify shipping terms upfront. Discuss contingency plans for delays (e.g., expedited production options). Sunmy Hardware provides transparent lead time estimates and works with reliable logistics partners to ensure on-time delivery—whether you’re importing USA custom hardware parts or European industrial components.

7. Poor Communication on Customization Flexibility

Buyers often assume manufacturers can accommodate last-minute design changes, but this isn’t always the case. Changing specs mid-production can lead to delays, increased costs, or compromised quality—especially for complex processes like injection molding for industrial components.

Solution: Communicate all customization needs (and potential changes) upfront. Discuss the supplier’s change order process, including lead time and cost implications. Sunmy Hardware’s strong development capabilities allow us to adapt to reasonable design changes, but we recommend finalizing specs before production begins to avoid disruptions.

8. Failing to Clarify Intellectual Property (IP) Protection

IP theft is a concern for many buyers sourcing custom parts. Without clear agreements, your designs, formulas, or proprietary information may be shared or replicated.

Solution: Sign a non-disclosure agreement (NDA) and IP protection clause with your supplier. Specify ownership of tooling, molds, and designs. Sunmy Hardware takes IP protection seriously—we require NDAs for all custom projects and ensure client designs are kept confidential.

9. Choosing Price Over Value (Low-Cost ≠ High-Quality)

Opting for the cheapest quote often backfires. Low-cost suppliers may cut corners on materials, labor, or QC—resulting in defective parts, delays, or costly rework. For example, a budget stamping service may produce stainless steel brackets with inconsistent dimensions, leading to assembly issues.

Solution: Focus on value, not just price. Evaluate suppliers based on quality, experience, production capabilities, and customer service. Sunmy Hardware offers competitive pricing without compromising on quality—our 8+ years of experience in custom parts manufacturing means we deliver cost-effective solutions that meet your standards.

10. Not Partnering with an Experienced OEM/ODM Manufacturer

Working with a generalist manufacturer instead of a specialist can lead to subpar results. For example, a supplier that primarily produces standard parts may lack the expertise to handle automotive components customization or precision machining for medical equipment parts.

Solution: Choose a manufacturer with experience in your industry and part type. Look for case studies, client testimonials, and relevant certifications (e.g., ISO 9001 for quality management). Learn more about Sunmy Hardware’s expertise—we specialize in OEM/ODM custom parts, with a focus on CNC machining, die casting, stamping, and injection molding. Our team’s deep industry knowledge ensures we understand your unique requirements and deliver tailored solutions.

Conclusion: Avoid Mistakes, Choose the Right Partner

Ordering custom parts from China doesn’t have to be risky—by avoiding these 10 mistakes, you can streamline the sourcing process, reduce costs, and get high-quality parts that meet your needs. The key is to prioritize clear communication, verify capabilities, and partner with a reliable manufacturer.

At Shenzhen Sunmy Hardware Co., Ltd., we’re committed to helping global clients navigate custom parts sourcing successfully. With our comprehensive production systems, strong development capabilities, and customer-centric approach, we’re your trusted partner for CNC machining service, aluminum die casting parts, custom lathe parts, and more.

Ready to avoid these mistakes and start your custom parts project? Contact Us today to discuss your requirements—our team will work with you to turn your drawings or samples into high-quality custom parts, on time and within budget.